Suspended permanent magnetic separator Customizable

¥0.00

A suspended permanent magnet separator is an efficient device that utilizes a high-intensity permanent magnetic system to generate a powerful magnetic field, designed to remove ferromagnetic impurities from bulk non-magnetic materials. It is widely used across various industrial sectors and plays a crucial role in protecting downstream equipment and improving product purity.

I. Structure and Working Principle

I. Structure and Working Principle

Structural Composition:

Core Magnetic System: Utilizes high-performance neodymium iron boron (NdFeB) permanent magnet materials, known for their high coercivity and high remanence, forming a composite magnetic system to ensure strong magnetic field strength and stable, long-lasting magnetic force.

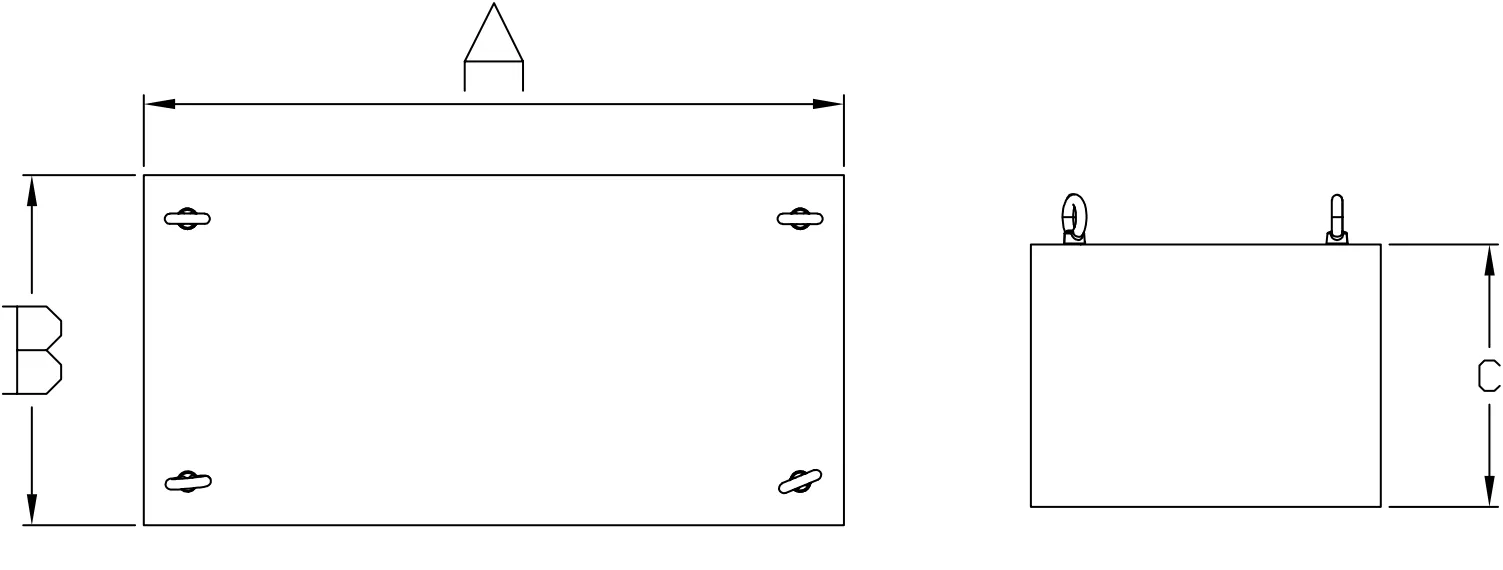

External Casing: Made from high-quality steel, it protects the internal magnetic system and provides a lifting structure for secure suspension at the work location.

Working Principle:

The equipment is installed above conveying equipment. As material passes beneath it, ferromagnetic substances (such as nails, screws, iron chips) mixed within the material are quickly attracted and adsorbed onto the surface of the separator’s magnetic system or onto a discharge belt due to the powerful magnetic field. This effectively separates the ferromagnetic impurities from the material flow, achieving purification.Manual Cleaning Type: Requires regular shutdowns for manual removal of adsorbed ferromagnetic material.

Self-Cleaning Type: Equipped with a discharge belt, drive roller, and other mechanisms, it can operate continuously, automatically ejecting adsorbed iron impurities away from the magnetic field zone, enabling automatic iron removal. Suitable for high-throughput, continuous operation scenarios.

II. Technical Features

Exceptional Magnetic Performance: High magnetic field strength, advanced magnetic circuit design, and great penetration depth enable effective absorption of deeply buried ferromagnetic impurities of various sizes and shapes.

Energy Saving and Environmental Protection: Operates entirely without electrical power, consumes no energy, generates no heat, and produces no noise pollution, meeting energy conservation and environmental protection requirements.

Long Service Life: The core permanent magnetic system does not age or degrade. Under normal operating conditions, its service life can exceed 10 years, with very slow magnetic force decay.

Easy Installation and Maintenance: Compact structure, small size, and light weight facilitate easy installation. Requires no special maintenance, offers stable and reliable performance, and can withstand harsh industrial environments like high temperatures and high dust levels.

III. Main Technical Parameters

| Parameter | Description |

|---|---|

| Suitable Belt Width | Various specifications available based on需求 (needs). Common range: 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, 1600mm, 1800mm, 2000mm, 2400mm, etc. |

| Suspension Height | Determined based on site-specific conveyor belt speed, material thickness, and iron removal requirements. Requires professional calculation; custom heights are supported. |

| Applicable Belt Speed | Generally recommended for conveyor belt speeds ≤ 4.5 meters/second. |

| Material Thickness | Typically effective for material thickness < 150 millimeters. |

Note: The above are general parameters. Specific model selection should be based on actual working conditions.

IV. Application Scenarios

Suspended permanent magnet separators are key equipment for material purification in the following industries:

Metallurgy Industry: Used for pre-processing raw materials like ore, coke, sinter, etc., to protect crushers, grinders, and other key equipment.

Coal Industry: Removes iron pieces from coal during washing, conveying processes to improve coal quality and prevent belt damage or equipment failure.

Building Materials Industry: Used for iron removal in raw materials like limestone, clay, clinker, pulverized coal in cement production lines, and quartz sand in the glass industry, ensuring production safety and product quality.

Other Industries: Also widely used in chemical, grain processing, ceramics, power generation, waste processing industries, etc., for removing various ferrous metals from materials.

V. Selection and Installation

Selection Points: Requires comprehensive consideration of material properties (particle size, humidity, iron content), conveying equipment parameters (belt width, speed, inclination), installation space, and iron removal requirements to select the most suitable model and specification.

Installation Methods: Typically suspended above the head (drive pulley) or middle of the conveyor, leveraging the material spread when抛起 (lifted/thrown) for optimal iron removal (effect). Can also be specially designed for installation in chutes or pipelines.